Cuando se emplea la expresión “tripa natural”, el nombre de Babolat sigue sistemáticamente. Pierre Babolat fabricó la primera cuerda de tenis de tripa natural en 1875 y lanzó la marca de cuerda VS 50 años después, la cual sigue siendo popular un siglo más tarde.

En la actualidad, la cuerda de tripa natural Babolat VS se elabora en la pequeña localidad de Ploërmel, en el corazón de Bretaña, en el noroeste de Francia, donde Babolat instaló una fábrica en septiembre de 1979 para aprovechar la proximidad con los mataderos de la región.

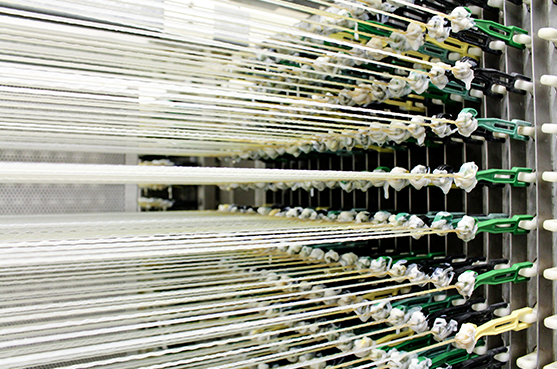

Actualmente son veinticinco los empleados que trabajan en la fábrica, estirando las tripas de vaca hasta 12 metros de largo (40 pies), antes de filtrar lo que se conoce como la membrana serosa y analizarla para buscar cualquier imperfección que pudiera debilitar la cuerda. A continuación, se trata la membrana con ácido acético durante 24 horas, se seca, se enrolla y se retuerce más de 1 500 veces hasta alcanzar un aspecto parecido al de una cuerda de tenis.

Davis Cup ‘Win’

The head of this operation is Erwan Grimault, who took the reins in 2014 – quite an important year, as it turned out. It was the year France lost in the Davis Cup final, but this Frenchman was not entirely unhappy about that.

“Such is the respect people have for Babolat’s gut strings,” Erwan says, “that plenty of players – including a significant number of recent Grand Slam champions – play with our natural gut. When France lost that final and the opposition’s leading player was playing with a hybrid set-up, half of his racquet was Babolat natural gut. So, while everyone in France was in tears because we’d lost the final, as far as I was concerned half of that Davis Cup win was due to French strings!”

These days few tennis players use a full string bed of natural gut. While it gives a great feel, it is harder to control the ball with only gut, so the optimum combination has become a hybrid of gut with polyester or monofilament – the gut for the feel and power, the synthetic string for the control. The mix of strings means a hybrid string bed has four knots, which means the tension is held better. A significant number of top 100 players on the ATP and WTA tours use hybrid stringing.

Yet Erwan Grimault is aware that some people are reluctant to string with natural gut. “Quite a few stringers are nervous about using it,” he says, “because it’s more expensive, so you don’t want to make a costly mistake. You have to be a bit more careful with gut, because if you crease it, you can leave a visible mark on the string.

“I was no expert, but I learned how to do it when I joined Babolat, and I don’t have a problem. Sometimes it slips a little more because it’s doesn’t have a synthetic covering – we use lacquer.”

Supplying the top players

The manufacturing process is a fascinating one, which requires vastly different skills at different stages, as Erwan explains. “The strings were originally made in Lyon, but production was moved to the north-west in the 1970s, and the first half of our work is wet processing, very much like in the agricultural industry. Then in the second half of the process, when we put the lacquer on, we’re much closer to the finished product.

“Since 2008, the factory has been carrying out every stage of the production process here in Ploërmel, and you see the strings in their packaging as they will appear when they’re on the shelves in a tennis shop. It takes a couple weeks to make one set of string, it is a labour-intensive manufacturing process. Then we perform tests on every batch of string that we make. We also put a code on each set individual set of string to track the batch. We take our craft and the quality of Babolat natural gut extremely seriously.”

Erwan follows the news from the tennis circuit. “Working here certainly makes a change from previous jobs,” he says. “We’re making a product with real value that is used by top players, men and women, and it gives me a tremendous sense of pride when I see a player achieving something with our strings.”